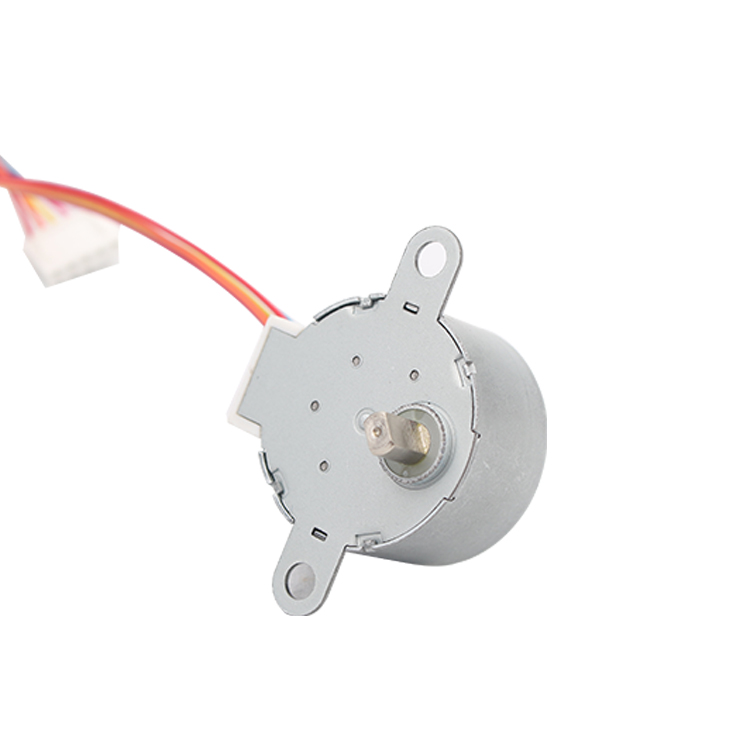

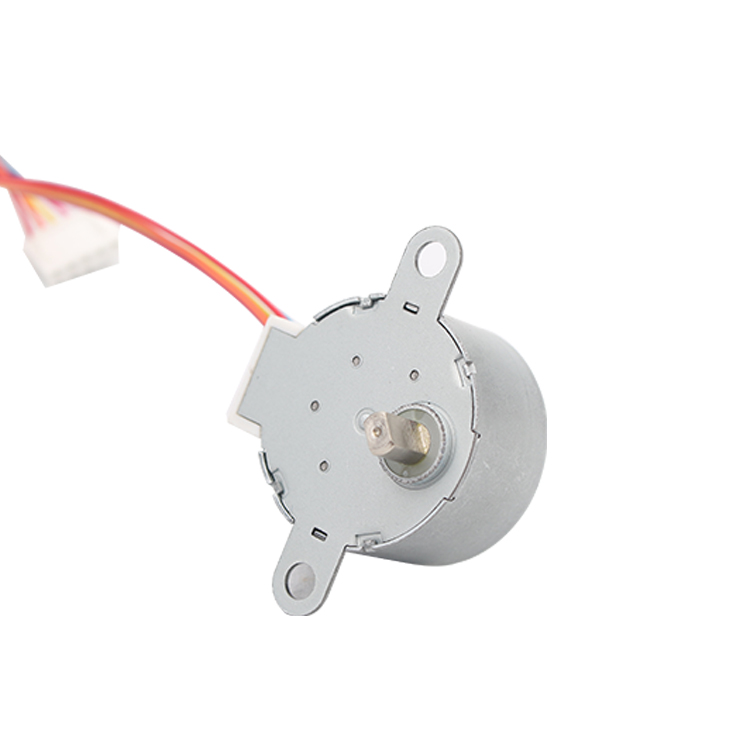

30BYJ46 Low Noise Permanent Magnet Stepper Motor with I Cut Shaft

12V 7.5 °/82.25 Step Angle $0.8~3/unit

30BYJ46 stepper motor is mainly used for sanitary ware.

Thermostatic valve Hot water faucet Automatic control and

adjustment of water temperature and water flow such as Rainwater.

At the same time, it can realize other fields that require precise

control. Due to the realization of open-loop control and low-cost

position control, it is widely used in various fields of gas

control, water purifier valves, instruments and other automatic

control precision control.

At the same time, the external wiring part can be used according to

customer requirements for various types and lengths of connecting

lines, or FPC FFC.

The output part can be used in various ways such as gears, pulleys,

V-grooves and turbine screws.

Our team has more than 10 years of stepper motor design,

development and production experience, so we can achieve product

development and auxiliary design according to the special needs of

customers!

Customer needs are our efforts, please feel free to contact us!

The shape of the mounting plate and the angle of the outlet can be

adjusted according to customer needs!

Mechanical Dimension:MM

Technical Features

30BYJ46 12V Permagnent Magnet Stepper Motor with I Cut Shaft

Application Highlights

HVAC/R Valve Actuation Winding possibilities – Bipolar

Office Automation Printers, Copiers, Data storage Maintenance free - motor is brushless

Medical Applications Pill dispensing Analysers Cost effective - compact design, lower integration cost

Other Industries & Applications Robotics Digitally controlled - Easy to use with a micro processor

Telecommunication Antennae positioning Switching lines Open loop

control - No encoders necessary

Typical Applications

In medical devices, 30 mm stepper motors are used in saliva

analyzers and hematology analyzers to control the precise

displacement and positioning of samples. In these devices, the

motors enable high-precision positioning control to meet the

accuracy requirements of the testing process.

In welding equipment, 30 mm stepper motors are used to control the

wire feed speed and pathway, and by controlling the motor speed, a

continuous and stable supply of wire can be achieved to ensure the

quality of the weld. Stepper motors are also used in fiber optic

fusion machines to control the alignment and feeding of the fiber.

In smart home and security systems, 30mm stepper motors are used to

drive the rotation of cameras for all-round surveillance. The motor

can achieve high-precision rotation control to meet the

requirements of image clarity in the monitoring process.

30 mm stepper motors are used to drive the movement of some

mechanical parts in digital electronics, such as the rotation of

the grating and the movement of the slider. Such applications

require motors with high precision, reliability and long life to

meet the requirements of precision instruments.

Specifications

| Product Name | Geared stepper motor |

| Model | 30BYJ46 |

| Resistance | 130 mΩ ± 10%/ phase |

Current Per Phase | 100 mA/phase |

| Max Starting Frequency | 350 pps |

| Max Response Frequency | 800 pps |

| Pull in Torque | 78.4 gf.cm |

| Detent Torque | 39.2 gf.cm |

| Operating Temperature Range | -0~+ 45 ℃ |

| OEM & ODM SERVICE | AVAILABLE |

Advantages

High precision. Stepper motors enable precise angular control and

positioning to meet the requirements of high precision

applications.

High torque. The torque of permanent magnet stepper motors is

larger than that of ordinary stepper motors, which meets the

requirements of large load applications.

Low vibration and low noise. PM stepper motors have a smooth motion

curve and low pulsation rate, which effectively reduces vibration

and noise.

No slip rings and gears. Permanent magnet stepper motors use a

permanent magnet yoke as the rotor, eliminating the need for slip

rings and gears, resulting in a simple and reliable structure.

Long life. Permanent magnet stepping motor has long life, high

reliability, and low maintenance cost.

Low electromagnetic interference. The electromagnetic interference

generated by the permanent magnet stepping motor is low and will

not affect the surrounding devices, which is suitable for

applications requiring low interference.

Self-locking capability. This self-locking feature eliminates the

need for additional mechanical locking devices.

Type of Wire Connect

Motor input method with Pin type,FPC, PCB, Lead wire etc.

These can be customized according to customer needs.

Shaft Type

Out shaft standard as follows,also can customerized due to the user

drawings

welcome to contact customer service for more types

Round Type : DIA3mm. 4mm. 5mm

D-cut Type: DIA3-D2.5 DIA4-D3 etc

Screw Type: M3 M4 M5 Serial

Trape Type

I-cut Type: DIA3-I2 DIA4-I3

Other Type: Shaft with a hole etc

Type of Fixture Cover

The regular models are shown in the figure, and the special sizes

can be customized.

Product Detail Presentation

Lead Time and Packaging Information:

Lead time for samples:

Standard motors in stock: within 3 days

Standard motors not in stock: within 15 days

Customized products: About 25~30 days (based on complexity of

customization)

Lead time for building a new mold: generally about 45 days

Lead time for mass production: based on order quantity

Packaging:

Samples are packed in foam sponge with a paper box, shipped by

express

Mass production, motors are packed in corrugated cartons with

transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets